With nearly a decade worth of experience in developing the CETO technology, SeaPower has generated strong competencies in idea generation and assessment, intellectual property management, engineering design, prototype manufacturing and testing and computational fluid dynamics testing. The latter allows ideas and designs to be tested rapidly in a virtual environment, prior to physical prototypes being built. Overall, these design competencies allow for rapid speed to market and return on investment, and reduce risks associated with full scale, in-ocean performance.

Initial development involved the building of scale models and wave tank testing:

Whilst scale models and wave tank testing are useful in developing preliminary designs and eliminating non-performing design elements, for wave power technologies, they are ultimately an inadequate way of developing a commercial technology. This is primarily due to the inability to extrapolate performance in a wave tank to full-scale designs in an ocean environment. The ocean is a highly complex environment and the only way to test prospective designs effectively prior to deployment is through the use of highly sophisticated computer models.

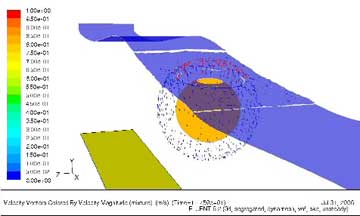

All CETO design elements are tested in a virtual ocean that is 250 meters long and of infinite width. Computational Fluid Dynamic modelling allows the simulation of the movement of the CETO device as well as calculation of any forces and pumping actions that are generated as a result. Motion of the Buoyant Actuator, wave creation and pump simulation are all controlled and measured by User Defined Functions developed by SeaPower Pacific.